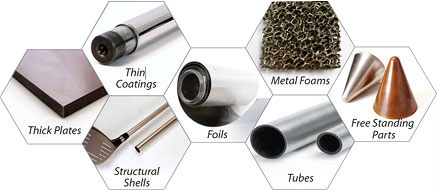

PowerMetal’s nanometals can be nanofused to a light weight substrate and used to cost-effectively produce micro- or macro-scale complex components.

What makes this material class unique is that unprecedented sporting

goods component design flexibility can be achieved because of the inherent

shape flexibility of net-shape manufacturing. The material can be

formed

into a myriad of shapes, which are simply dependent upon the shape

of

the substrate onto which the nanometal is deposited. In addition, the

material can be nanofused to metal, graphite/epoxy composites,

plastics - even wood - and can achieve material thickness distributions

unattainable with conventionally processed metals. It may even be used

to bond entirely dissimilar materials.